Product information

- Most compact briquette press on the market

- Ideal for small and medium-sized carpenters’ workshops

- Briquettes with a diameter of 54 mm

- Pressing briquettes without the use of binders

- Stable hopper with screw loader

- Cylinder controlled by sensors which reduces wear and maintenance costs

- Separate motor for propeller and feeding unit

- Adjustable pressure of the pressing chamber for high quality briquettes

Description

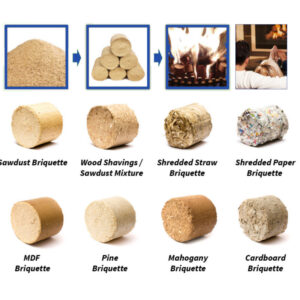

To make briquettes from sawn wood, sawdust, filter dust, and other similar materials. The material to be processed is put into the 102-litre capacity bin. The feeder continuously fills the channel of the pressing unit. The transit brings the material to the pre-compressor. A hydraulic cylinder pushes the material into the press chamber. The press pieces, which are also hydraulically controlled, press the material together in connection with a specially hardened press cylinder and guarantee excellent briquette quality. The compressing process is carried out without binders. The maximum humidity of the material must not exceed 15 %. The machine makes a quantity of briquettes between 10 - 20 kg per hour, but can vary due to the different materials used. The briquettes automatically come out of the machine at approximately the same length. High reliability, almost no adjustment by the user. Filling cylinder with silent operation and long service life. Stable hopper with screw loader and feeder. The cylinders are controlled by sensors. Advantage: low wear, reduces maintenance costs. Separate motor for the propeller and feeder.

Adjustable pressure of the pressing chamber with the advantage: high quality of the produced briquette adapted to the used material.

Reviews

There are no reviews yet.